Why Choose MeriCrusher?

READ BELOW WHY MERICRUSHER MULCHERS

ARE THE BEST CHOICE FOR YOU

Low Operating Costs

- 20-40% lower fuel consumption

- Longer cutter life

- Reasonably priced carbide cutters

- Lower power demand

- Multiple cutter options available

MeriCrusher stands out for its cost-effectiveness due to several key features. Their lightweight design makes them compatible with smaller, less expensive tractors. They are equipped with standard conical carbide cutters, which are more affordable than specialized custom cutters. Additionally, the lower rotor cutting speed in MeriCrusher, which is about 20-30% slower than rival machines, results in longer-lasting cutters. This reduced speed significantly decreases the wear rate on the cutters and other components, which typically escalates with higher speeds. Moreover, the lower cutting speed paired with high torque leads to substantial fuel savings, potentially up to 40% lower than what is observed in competing machines. MeriCrusher rotors also offer the versatility of accommodating different types of cutters simultaneously within the same rotor.

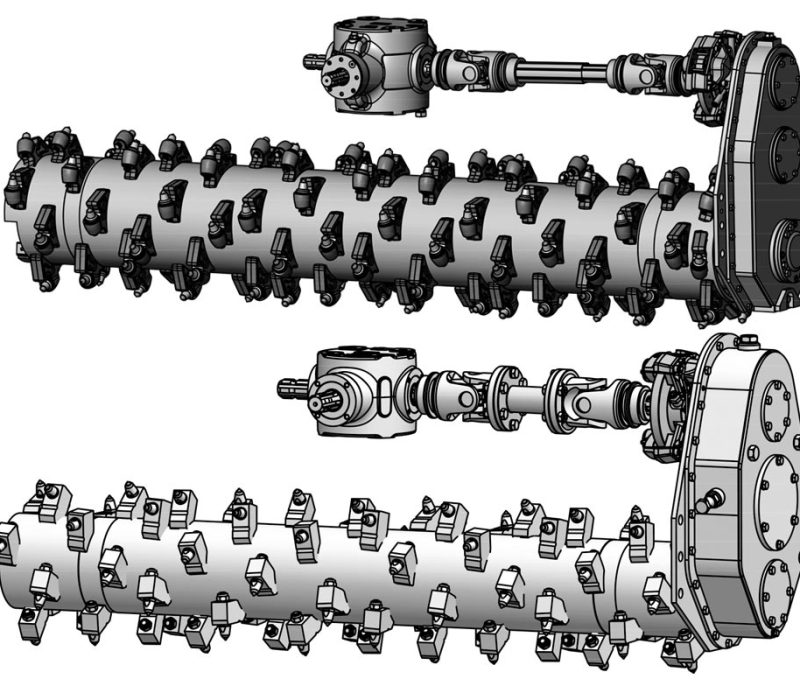

Deeper Subsoiling with Low-Speed and High-Torque Rotors

- Deeper into the ground 20 – 40cm

- 20-30% higher torque

- No need for rotor balancing

- Safer to work near buildings

- Eliminates the undergrowth roots, stumps etc.

MeriCrusher rotovators excel in subsoiling, reaching depths of 20 to 40 centimeters. Even our smallest models provide deep subsoiling, which eliminates roots when land clearing. Unlike high-speed mulchers from other manufacturers, which disperse soil and wood chips over existing roots, promoting rapid regrowth of undergrowth, MeriCrusher mulchers are purpose-built for sub-surface work.

MeriCrushers are designed from the outset to work beneath the surface.The key distinction of MeriCrusher lies in their rotor’s cutting speed and torque. Our rotors rotate more slowly yet with higher torque, making them adept at penetrating deep below the surface, even when powered by small tractors and in stony soil. The cutting speed in our mulchers is 20-30% slower compared to other brands, but torque is the critical factor for below the ground. The slower cutting speed, combined with enclosed rotor chambers, minimizes the scattering of crushed material, enhancing safety, especially near buildings. Additionally, the lower speed negates the need for rotor balancing, offering a significant maintenance benefit.

Patented Sizing Screen

- Unique patented solution

- Extremely fine crushing result

- One machine for above and below the ground

- Versatile for different tasks

The MJS/G, MJHS, and MJFS series of mulcher rotovators offer an optional sizing screen that enhances their functionality by producing exceptionally fine mulch. This feature integrates the crushing and screening process into the mulching activity, thereby streamlining the operation and eliminating the necessity for a separate high-speed mulcher. Instead, subsoiling and extremely fine mulch can be achieved with one machine. The inclusion of the screen makes the crusher more versatile. All the organic material is forced to come out through the screen holes which makes the result very fine.

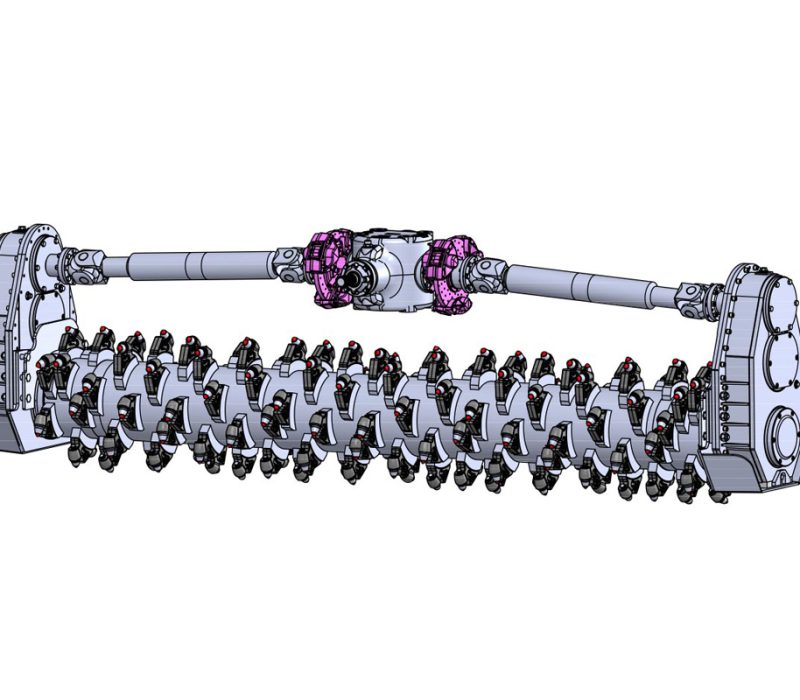

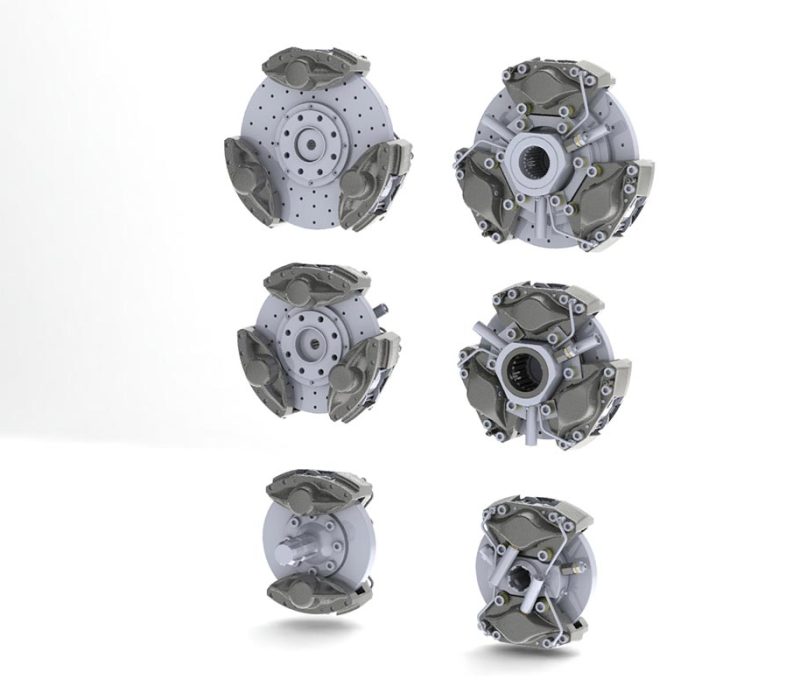

Reliable Transmission Solutions for Wide Power Range from 50 - 768 horsepower

- Unique patented POC-safety clutch

- Clutch solution which can withstand heat and high torques

- Reliable gear transmission solutions up to 768 hp

- In-house design and manufacturing

- No need for oil coolers

- Electric slip alarm

Our largest model stands out in the industry with its capability to handle up to 768 horsepower, significantly surpassing the typical 400 to 500 horsepower range of other brands. This exceptional performance is achieved through the use of our custom-designed side gears and our patented POC safety clutches, which are developed in-house. The main clutch components are the same as those used in automotive brake calipers, allowing them to withstand the heat from slipping without damage even when they become red hot. This slight slippage is crucial as it safeguards both the mulcher and the tractor’s transmission from peak loads that could potentially harm the transmission and engine.

The clutch’s design allows it to maintain consistent torque and friction across all speeds, even when temperatures rise, and it’s easily adjustable to match the tractor’s power. This feature, combined with a lower rotating speed and a substantial oil volume, means our side gearboxes do not require complex oil circulation and cooling systems, even when operating at high horsepower levels.

Additionally, our POC clutch can be fitted with an optional electric slip alarm. This feature alerts the operator when slippage occurs, further enhancing safety and ease of operation.

Wide Range of Working Widths up to 3.5 Meters Wide

- Working widths from 1.2 to 3.5 meters

- Wider than the tractor

- Less driving times/acre

- Optimized width increases productivity

- Fewer tire punctures

Our mulchers offer a versatile range of working widths to match the size of different tractors. Notably, our broadest models measure 3.5 meters in width, aligning with the width of standard tractors equipped with dual tires. Despite this expansive size, our 3.5-meter crushers maintain a weight comparable to 2.5-meter mulchers from other manufacturers. This width advantage is particularly beneficial in large-scale projects, as it reduces the number of passes required per acre.

Our own gears and safety clutches enable the power required to be transmitted safely through the transmission.

Light Weight and Strong Structure

- Less weight, more productivity

- Less stresses to tractor

- Better access to wet and soft conditions

- Safer to work in challenging terrain

MeriCrushers weigh significantly less compared to similar-sized models from other manufacturers. This design stems from our long-standing tradition of crafting machines for use in wetlands, where a lighter weight is crucial.

Being lighter, these mulchers can be operated with smaller, less expensive tractors, leading to cost savings. Additionally, when attached to a tractor’s rear linkage, a lightweight mulcher enhances safety, especially in challenging terrains. Our focus on a light structure has driven us to engineer our machines with precision, ensuring that steel is utilized efficiently and strategically. This approach ensures that strength and durability are not compromised, despite the reduced weight.

Ideal Solutions for Multiple Applications

- Mulchers for Forestry

- Mulchers for Agriculture

- Mulchers for Construction

- Mulchers for Road Construction

MeriCrusher’s range of soil tillers, mulchers, and road crushers offer an ideal solution for a multitude of tasks across forestry, agriculture, and construction fields. These versatile machines are designed to meet the varied demands of different environments and operations, providing a comprehensive answer to the challenges in these sectors.

50 Years Experience

With over 50 years of experience in designing machines for challenging conditions, we have established a reputation for serving demanding customers. This expertise includes more than 30 years of designing and producing MeriCrushers.

Our journey began with our crushers working beneath the ground, primarily in the peat industry, a sector highly sensitive to weather conditions. Given the limited number of production days annually in this industry, our machines are built to operate relentlessly, often 24/7. This background has underscored the critical importance of readily available spare parts. We ensure that these parts are accessible from our stock at all times, day or night, throughout the year.

Our commitment to durability and reliability is further evidenced by the longevity of our machines. It’s not uncommon for us to see videos of our machines still in operation after more than 40 years, a testament to the quality of our products.